SP-23

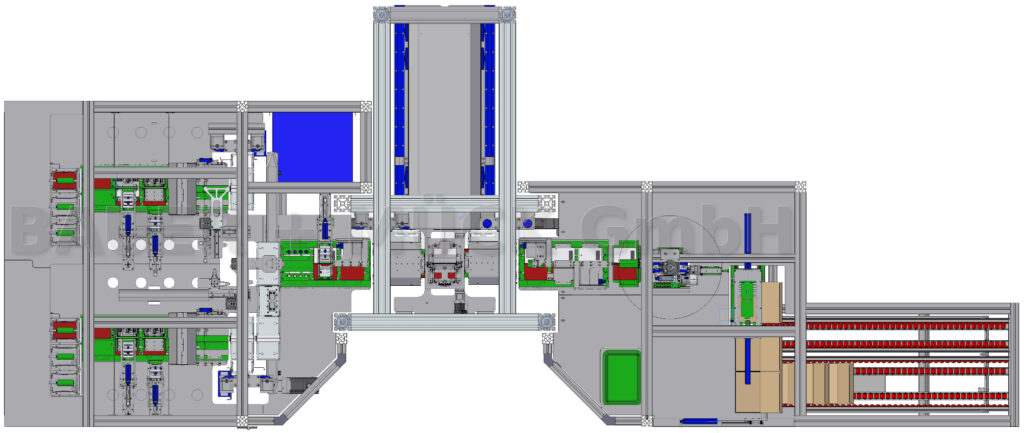

SP-23 fully automatic passport personalisation machine

- Fully automatic high speed personalisation machine for passports with distribution module

- High quality laser personalisation with grayscale photo and resolution up to 1200 DPI

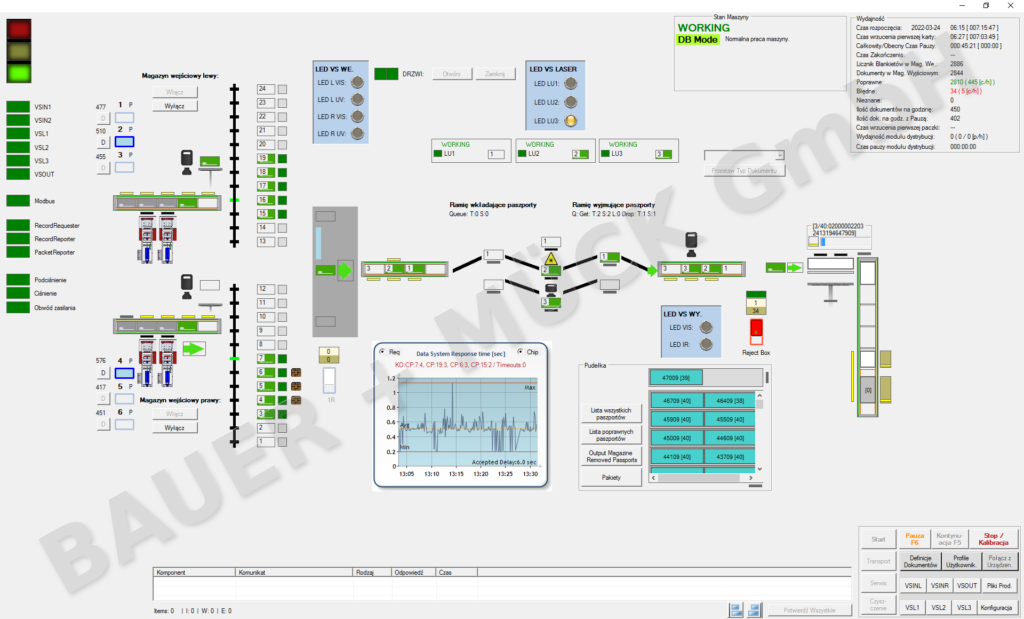

- Graphical user interface with detailed presentation of all activities and documents within production process

- Performance in continuous operation: 500 passports/h (inspection, chip personalisation and verification, laser engraving with high resolution photo, MLI/CLI and distribution module)

Input stack holders

- 2 modules with 3 input stack holders for 40 booklets each

- Machine switches off input stack holder automatically when all booklets from batch are taken

- Automatic detection of passport orientation

- Automatic opening of booklet cover and data page

Chip personalisation

- Chip station: 2 modules with 12 contactless programming units each

- Depending on the typical chip programming time, the matrix may be equipped with suitable number of chip programming units and their number may be extended later if necessary

- Chip verification to check the integrity of the data and the conformity of the visible and electronic layers of the document

Visual inspection (before laser engraving)

- Visual inspection and measurement of blank document

- Vision system developed in-house for maximum flexibility

- Document serial number readout

- Individual or global positioning of each engraved element

- Inspection in visible and optional UV light

Laser engraving

- Stable and robust laser source

- Superb contrast and grayscale depth

- Resolution up to 1200 DPI

- Microtext, tactile engraving and other security features

- CLI / MLI / SLI® capability with multiple angles per document

- Tilt angle of each layout element up to ± 30 degrees, user-defined

- Optional: color photo capability Lasink™ Origin and/or Lasink™ Helios

Visual verification (after laser engraving)

- Visual verification: OCR, OCV, barcode, 2D code reader (QR, datamatrix etc.)

- Vision system developed in-house for maximum flexibility

- Verification in red or optional in IR light

Reject box

- Reject box at the end of the transport system

- A booklet may be considered defective and destined for reject box. The reason for rejection will be included in the report

Distribution module

- The machine works with two types of boxes, designed for 20 and 40 passports, respectively

- Every second passport book is inserted in the box with a twist. This provides a better distribution of those and also improves ergonomy when removing and counting

- The report is generated for each box indicating the contents

Graphical user interface

- Detailed presentation of all activities and documents within production process

- Personalisation statistics and individual reports for all documents

Performance

- Performance in continuous operation: 500 passports/hour (visual Inspection, chip personalisation and verification, laser engraving with high resolution photo, MLI/CLI, visual verification and distribution module)